MACHINE CONDITION MONITORING IN WEST SUSSEX

Vibration analysis is an essential tool used in predictive maintenance and condition monitoring for machinery and equipment. By continuously measuring and analysing vibration levels, it helps identify irregularities that may indicate underlying issues or potential failures in machines.

This monitoring helps in identifying potential issues such as imbalance, misalignment, wear, or mechanical faults early, allowing for timely maintenance and preventing costly breakdowns or failures.

Predictive Maintenance & Condition Monitoring

Implementing vibration monitoring will enable you to minimize maintenance costs and maximize your plant availability. Vibration monitoring surveys offer a huge money-saving method of reducing downtime, meeting Health & Safety Legislation, and planning repairs within your planned shutdowns.

Monitoring relies on the use of accurate and reliable sensors, analytics, and diagnostic software and provides asset protection in a wide variety of industries, this is a fantastic tool for detecting faults in most types of rotating machinery.

Here are a few of the common faults that cause machinery failure:

- Bearing Defects & Wear

- Gearbox Faults

- Drive Belts & Pulley Wear

- Misalignment

- Unbalance/Fan Rotors

- Motor Defects

These can all be detected when using vibration analysis and monitoring.

How we can help

Vibration analysis has proven a highly effective method of measuring machine condition and we have the expertise to diagnose faults, allowing repairs to be scheduled within maintenance routines. We work in all industry sectors from building maintenance, pharmaceutical, heavy industry, and small business.

Our Vibration Surveys will provide you with:

Identify and diagnose faults in machinery before they lead to larger, more costly issues.

- Optimize equipment performance by identifying areas for improvement.

- Increase equipment reliability and reduce downtime by addressing potential issues before they cause a breakdown.

- Reduce maintenance costs by scheduling maintenance based on actual equipment condition rather than a predetermined schedule.

- Improve safety by ensuring that equipment is operating within safe vibration levels.

- Monitor changes in vibration levels over time to track equipment performance and health trends.

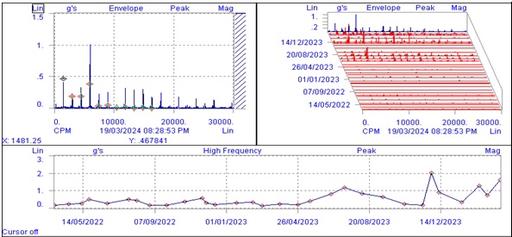

Example vibration spectrum below from a Pump showing an increase in bearing wear and a bearing clearance problem:

Contact our Vibration Experts Today

For more information about predictive maintenance contact our friendly team today on: 0208 108 0440.

Contact Us:

.svg.png?size=md)